Makeglow

MakeGlow is an easy-to-assemble, low cost, fully functional solar lantern made of recycled cardboard. It is intended to be built by students between 13-17 years from schools in rural India as part of an educational module. The product is designed to create awareness about solar technology through a hands-on experience in classrooms where students build their own MakeGlows.

Why Makeglow?

1 in 4 houses lack access to electricity in India.

i.e., 25% of the population i.e., 18,452 villages i.e., 300,000,000 people

Most people in rural areas use kerosene

Fact: "An evening of breathing in kerosene fumes is equivalent to smoking 2 packets of cigarettes."

kerosene is a dirty fuel and its fumes are harmful beyond imagination.

Here are a ton of reasons to justify why it's really bad:

It causes more than 500,000 premature deaths* per year in India.

Kerosene fumes cause indoor air pollution.

Kerosene contributes to greenhouse gas emissions.

Poor illumination quality causes eye strain and poor vision.

Women and children are most affected as they tend to spend more time indoors consuming kerosene fumes.

*According to U.S. Environmental Protection Agency.

The obvious next question is:

has solar not replaced kerosene?

After a lot of research, I came upon the following stats.

10% of this population uses solar.

50% of this population still uses kerosene.

"My interest was in researching where it was going wrong, if at all it was going wrong with all the solar lanterns in the market".

I identified a design opportunity there.

Problem Finding

I researched more into why people weren't buying solar. And of course, that also meant talking to many-many people to try and understand the issue from their point of view. Here are the three major reasons I identified:

Lack of awareness

Solar is an unfamiliar technology to an illiterate/impoverished population. There is inadequate education on sustainable lighting practices compounded by a high level of illiteracy. This results in an inability to make an informed one-time investment in solar lanterns and therefore, people still rely on buying kerosene everyday. Among the rural Indian population, there is a preconceived notion that solar is not viable and that only power generated from the central grid is real. Even when offered as a solution, villagers refuse to accept solar as a potential form of energy that could solve their day-to-day light related needs.

Lack of post sales support service and maintenance

The solar lanterns are not locally produced which make it difficult for people to repair and maintain them. Also, most people from low-income rural communities cannot afford repair technicians for imported technologies or appliances.

Cost and quality

Most solar lanterns are priced between $15-$35 which represents a significant one-time investment for a majority of the low-income families in rural India where the average daily income is $0.43 per household (~$11 monthly). This high cost puts solar lanterns out of reach for most people. The lower priced solar lanterns fail to gain consumer trust due to poor quality and bad product design.

The scenario now

I tried to understand what people from rural areas in India really thought about solar. Here are a couple of statements that best summarise the current scenario :

"(we) accept solar lanterns as welcome gifts but not as alternatives to kerosene."

"...(solar lanterns)...one time use objects."

"...second class alternatives to electricity."

"...solar is fake electricity. Give us something real."

"..too expensive and foreign."

After some major unpacking, I realised that a lot has to do with people's beliefs and preconceived notions about the technology stemming from lack of awareness.

Framing the question: what can be done to change people's attitude towards solar?

Proposed Idea

A low-cost Do-It-Yourself solar lantern to raise awareness in the rural communities in India.

How does it work?

The $5 MakeGlow kit consists of Solar LED components and a traceable template. The shape needs to be first traced on a piece of recycled cardboard. It can then be folded and the components attached to take form into a fully functional solar lantern. This product enables people to make their "own" solar lantern during which they get to understand how solar technology works. This lantern building activity acts as a platform to raise awareness while establishing trust for the technology among the people making it. The idea is to familiarise the technology thereby attempting to debunk misconstrued myths which in turn creates a receptive market for solar technology in the rural community.

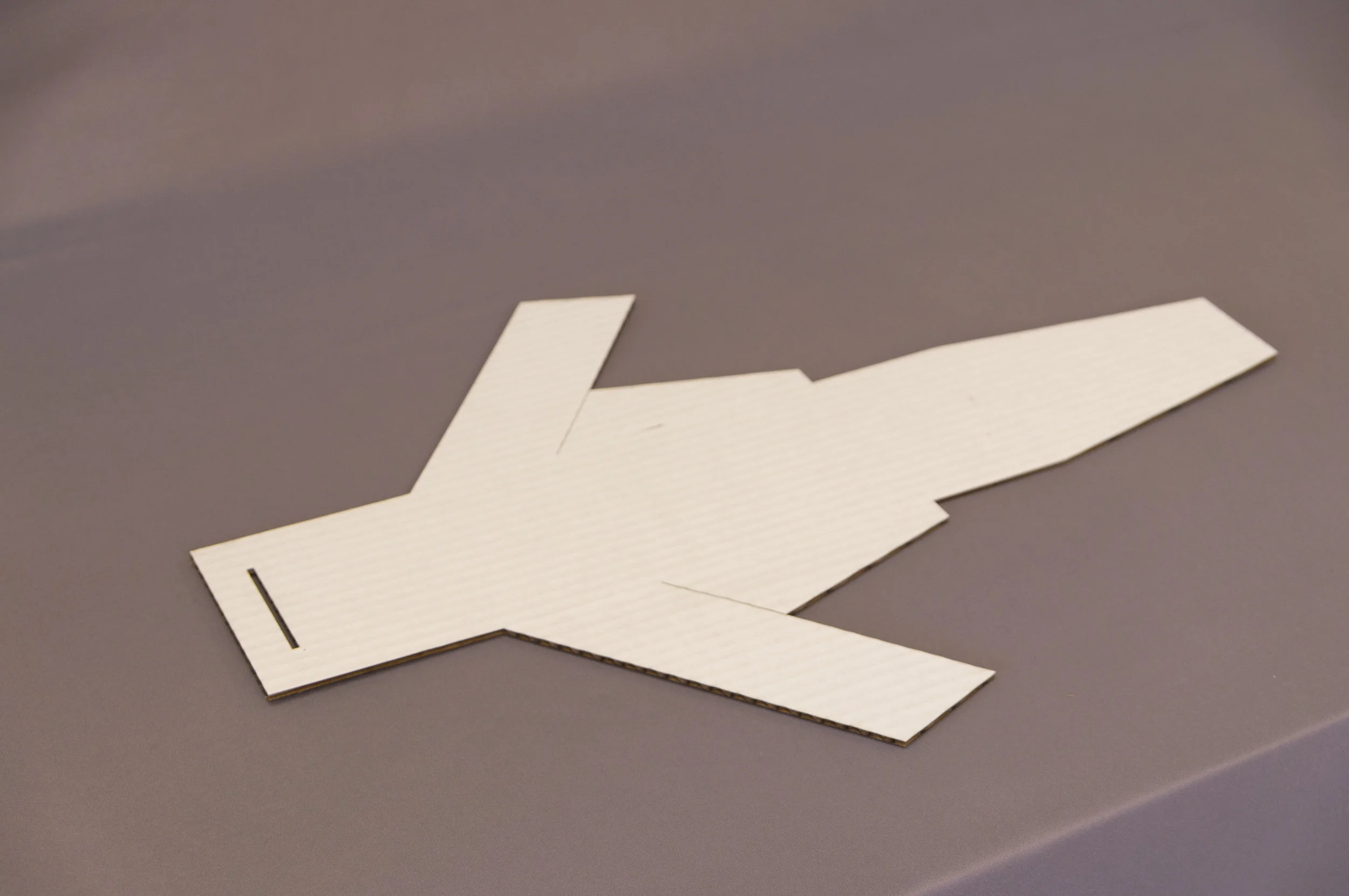

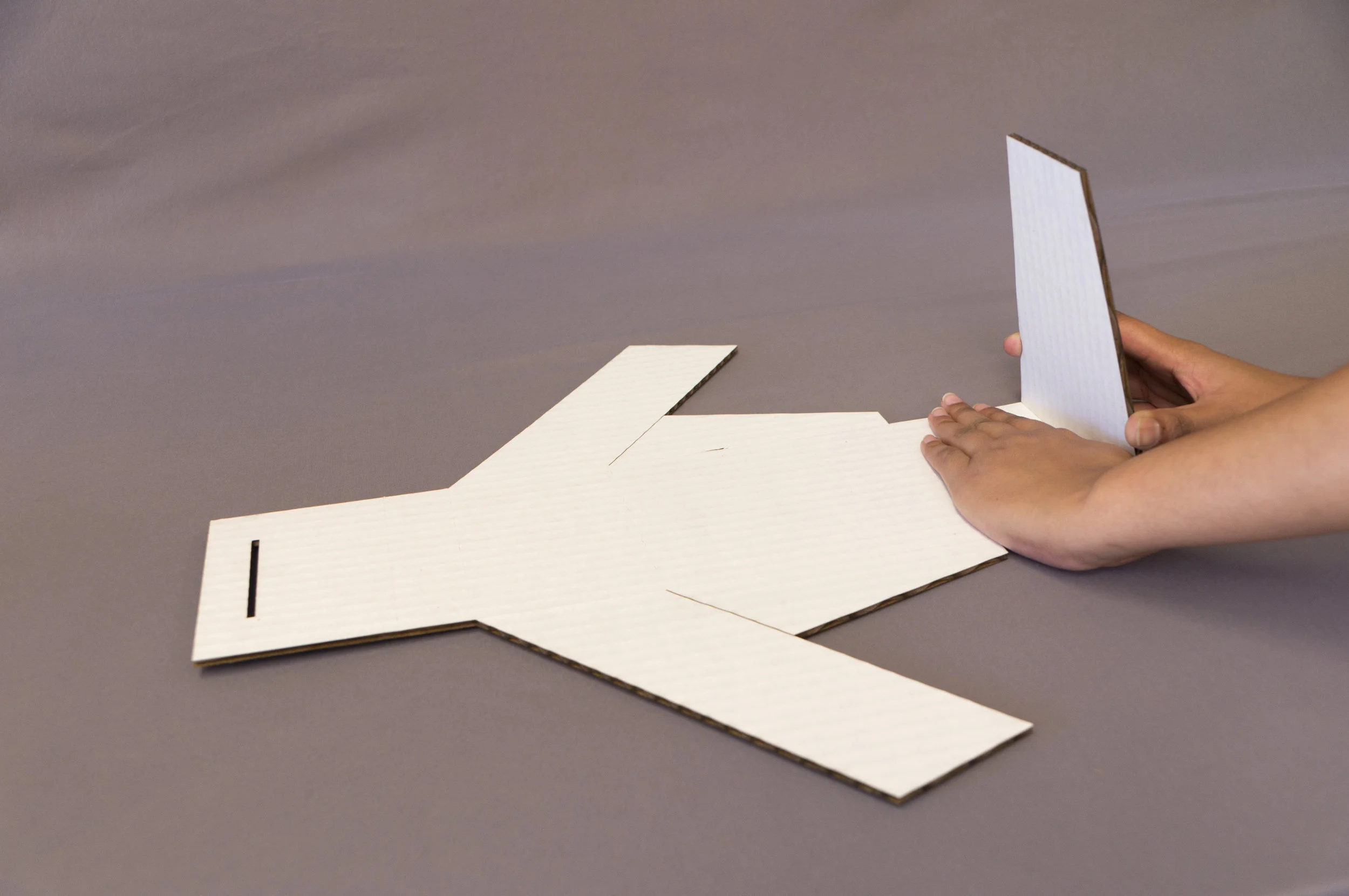

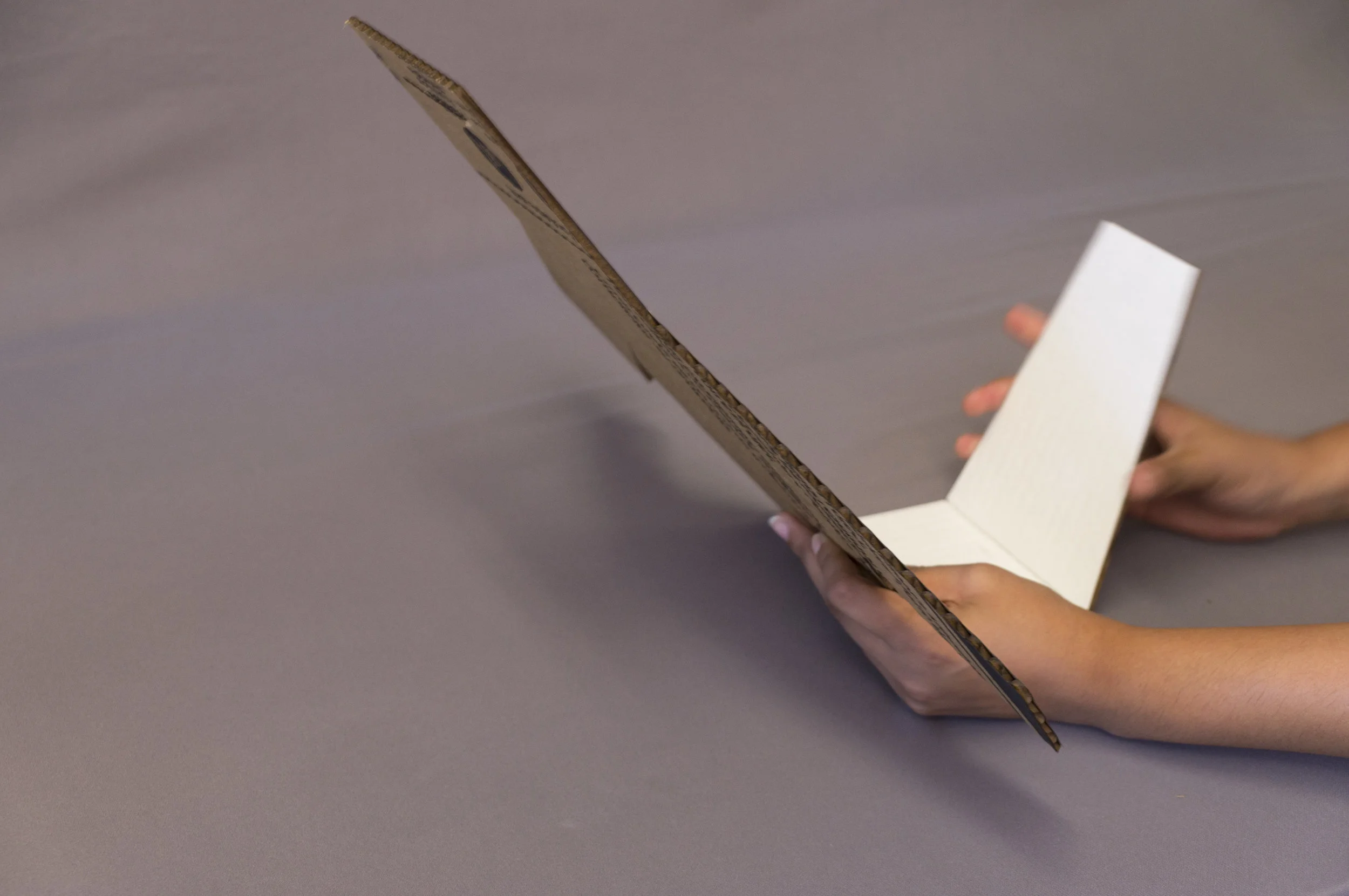

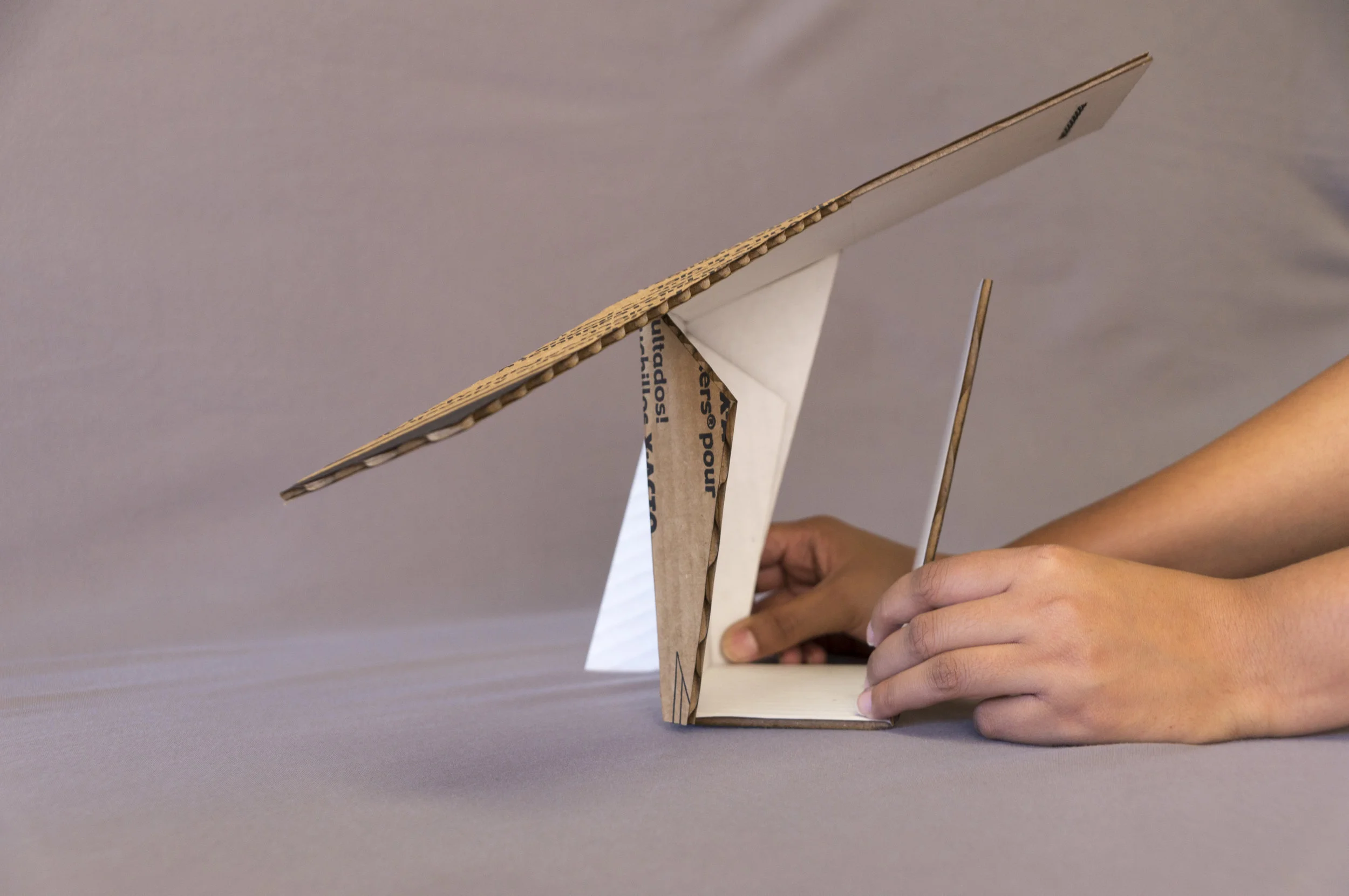

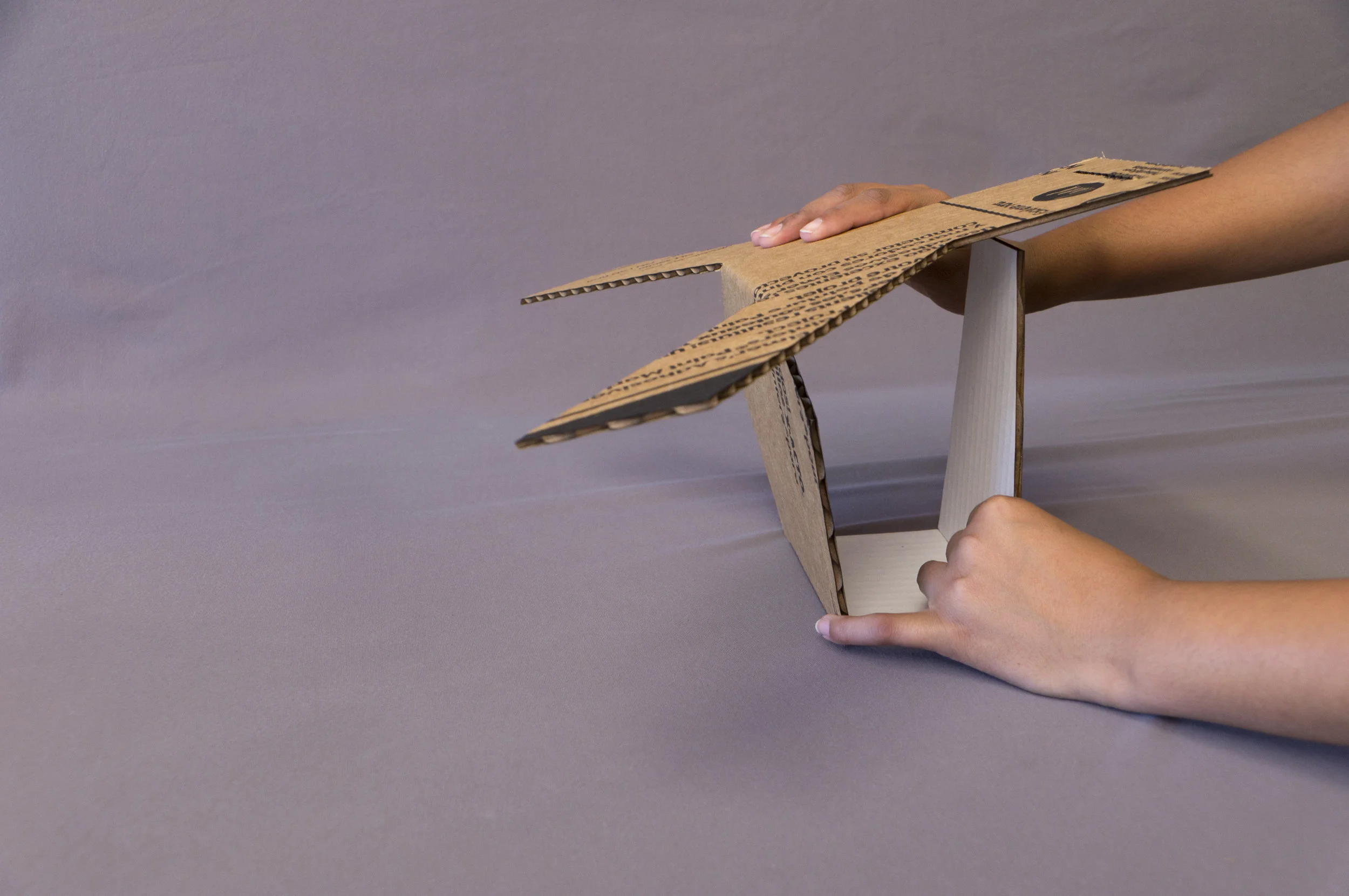

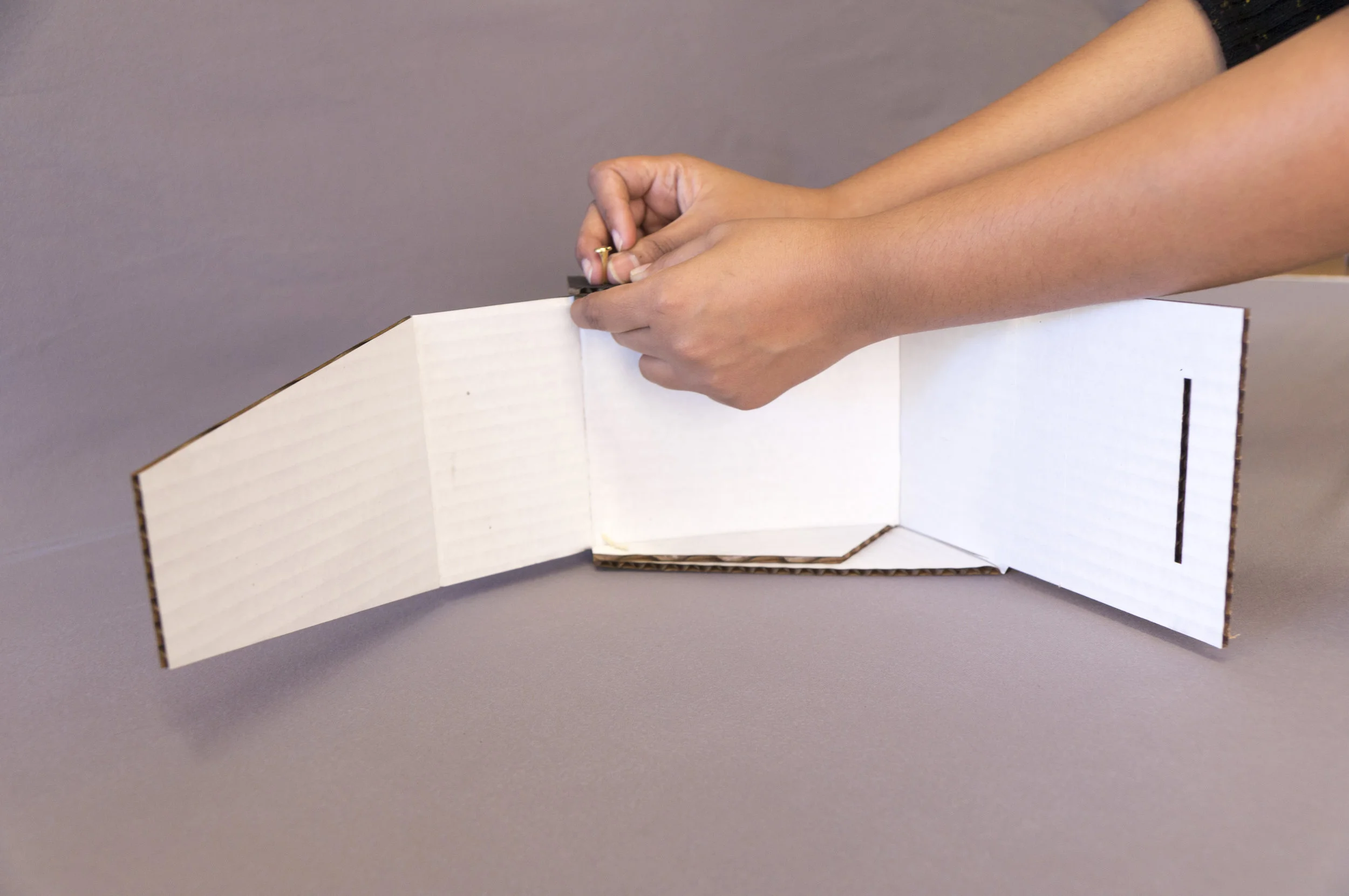

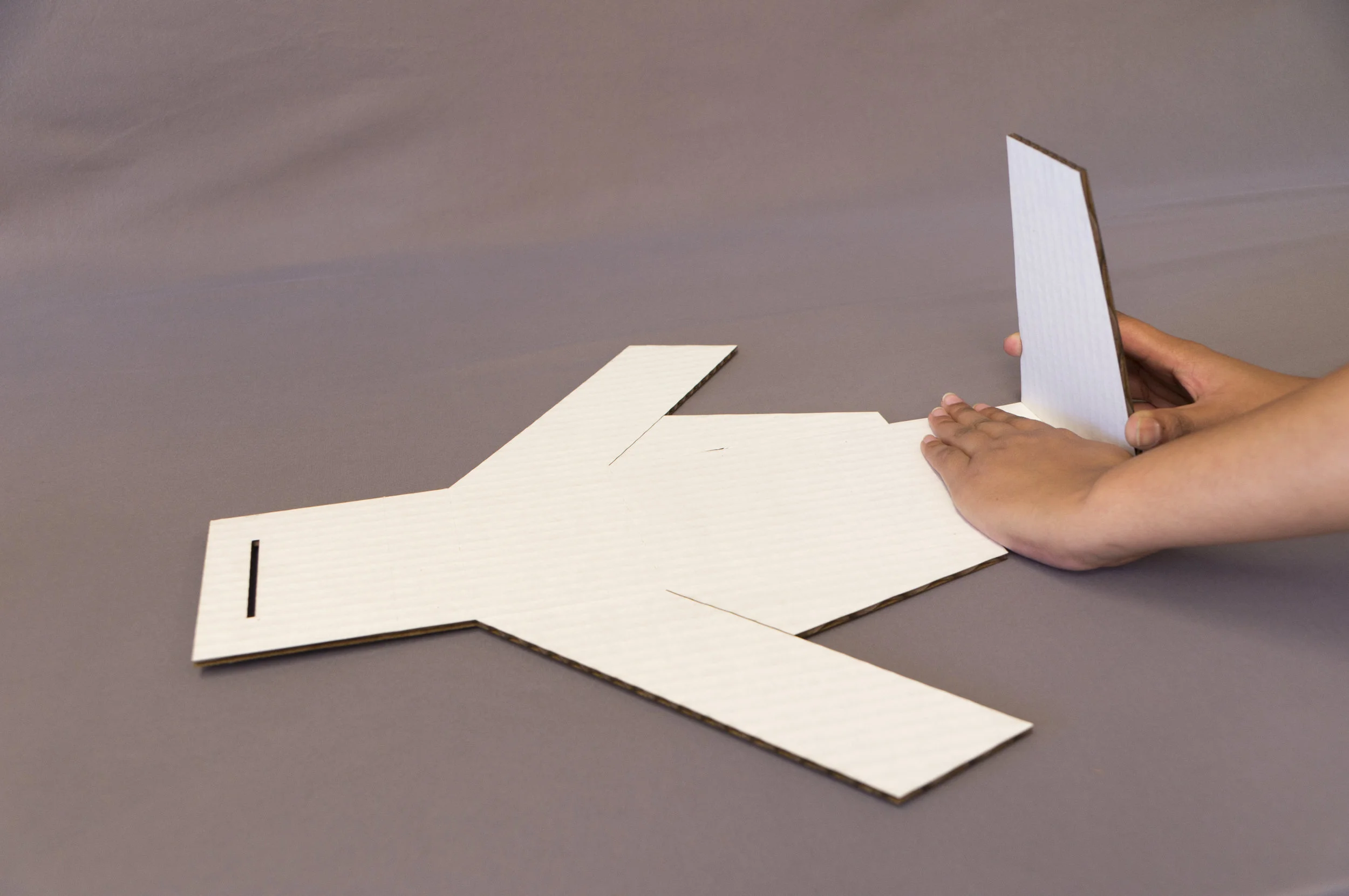

The folding process

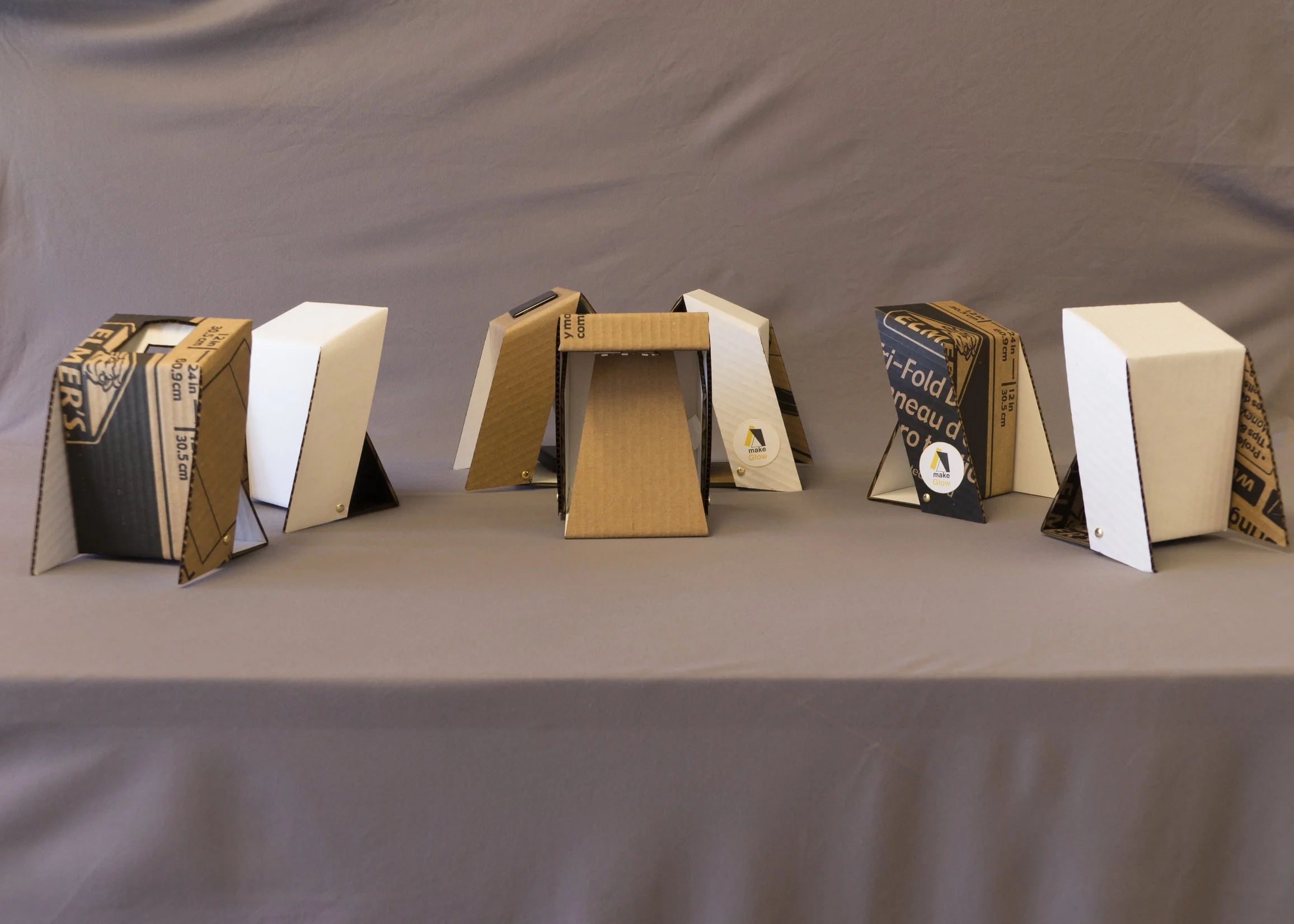

makeglow features

Easy to assemble

The folds are intuitive and can be easily done. The cardboard needs to be scored along the fold lines for achieving perfect folds. The lantern structure is secured with two paper fasteners that connect two flaps on the sides of the lamp.

Power source

A 5V solar panel is used to charge a 3.5V Li-ion battery that in turn powers a 3.6V LED light strip. The electronic components are inserted in square slots (also cut on cardboard using the template).

The design process

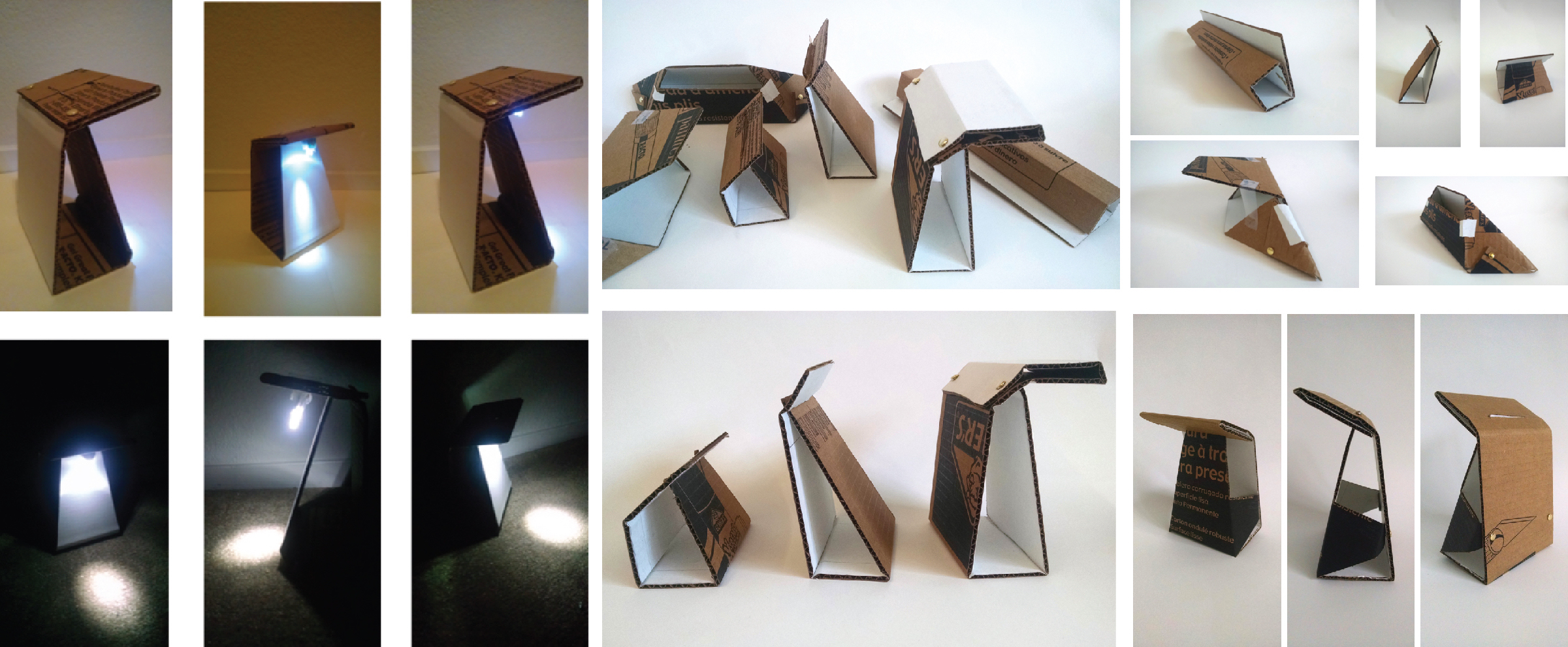

MakeGlow went through a series of iterations to reach the final form. My design process started with sketching two-dimensional templates on cardboard scraps and folding them into three- dimensional forms. With every iteration, I modified a certain aspect of the lantern structure to make it sturdier than the previous form. I decided to fit the entire geometric template onto a cardboard piece of dimensions 18x24 inches, partly because this is the general dimension of the side face of a packaging box and also partly for efficient prototyping purposes because this is the dimension of the side face of a packaging box and also partly for efficient prototyping purposes because this is the dimension of the laser cutter bed in Cruess Hall, UC Davis.

Evolution of templates used for laser cutting

prototyping and form finding

Solar circuitry of the Prototype

After carrying out tests and experiments on the circuits of various solar lamps available in the market, I decided to use Sunbender’s DIY Solar LED kit and integrated it with MakeGlow’s structure. However, this kit priced at $22 is expensive and does not reflect MakeGlow’s goal of a low-cost solar lantern. Therefore, this kit is used in the prototype as a mock up. In the future, I plan to develop my own solar circuit consisting of low-cost electronic components to keep the total cost of MakeGlow in the range of $5-6. With respect to this, I have carried out extensive research with respect to the pricing of various components when bought in bulk (100 pcs) and have estimated the cost of components as follows: 5V Solar panel: $1.80, 3.6V LED strip: $1.20, Li-ion rechargeable battery: $2.00, Wiring and transistors: $1.00. Total cost of components: $6.00.

What makes makeglow unique?

Studies have shown that the external casing and the assembly of solar lanterns account for 30% of the total cost. This is being cut down in a MakeGlow lamp as it uses recycled/ discarded cardboard and is self-assembled (DIY), lowering the overall cost by $10-$20 to just $5- $6.

An Application

integrating makeglow building activity in the school curriculum and offering it as a classroom program in rural schools in india.

Identifying a specific target group

School students from rural communities.

Students are possibly the best target group in the rural community to be introduced to new technology as they are enthusiasts, receptive to learning and break stereotypes. They have the power to influence their parents and as the future community members, have the power to change how solar technology is currently viewed.

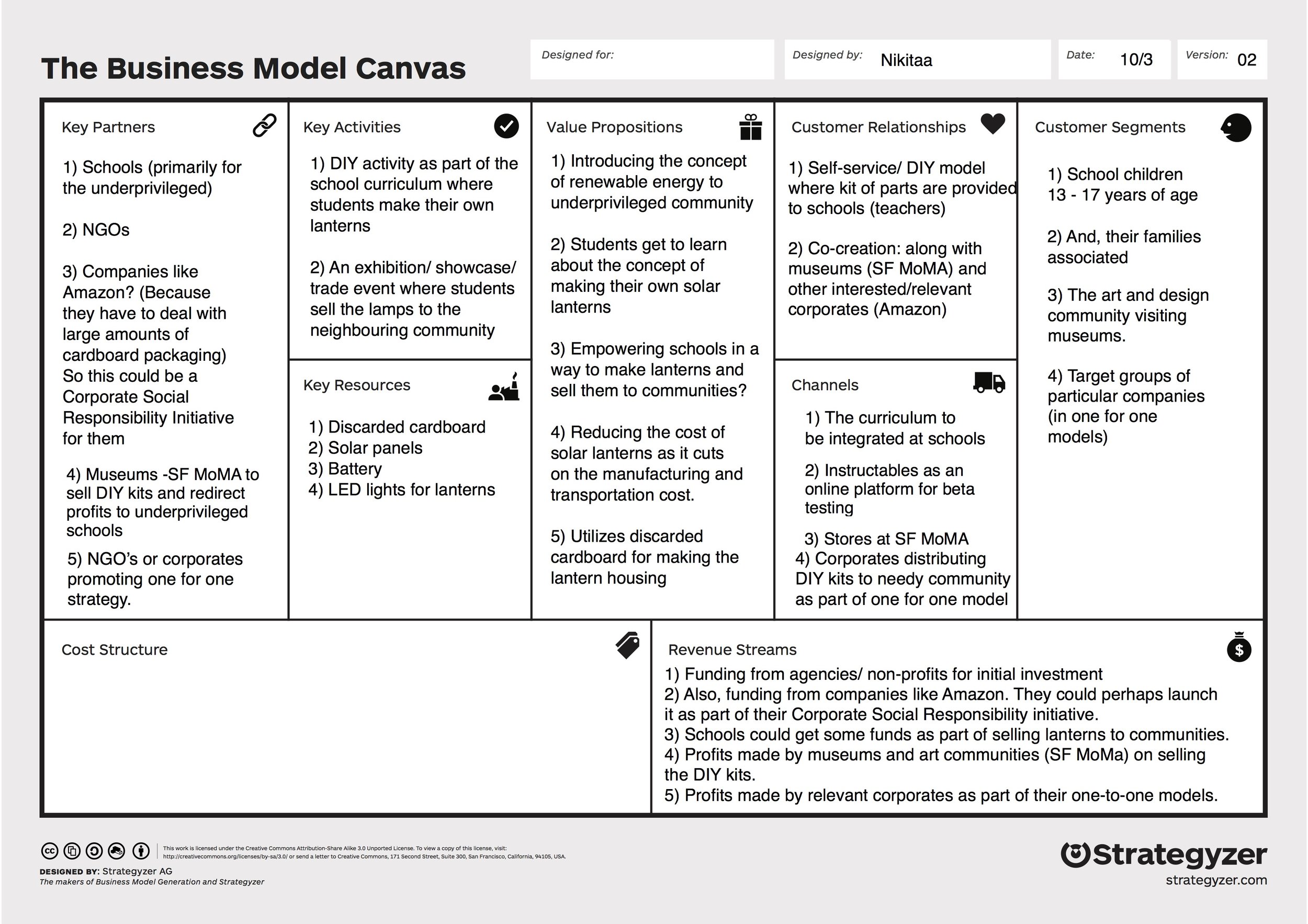

System Design

With external seed funding, the school (our target school is typically from rural communities) would purchase MakeGlow kits for a class of students. The teacher would then teach basics of solar technology to the class and introduce important concepts, referring to the MakeGlow teaching manual. In the hands-on building session, students will refer to a step-by-step process of building MakeGlow in the instruction manual. The students will first draw/trace the template onto a piece of cardboard. The cardboard will be sourced locally from thrift stores/general stores/recycle bins. The students will then cut the cardboard using xacto knives. Following the instruction manual, they will fold them into the final lantern structure. Next, using lead free soldering techniques and necessary precaution to connect the negative and the positive wires between the solar panel, battery and the LED, students will glue the components onto the cardboard piece. The placement of the various components is also indicated on the instruction manual and the template is so designed to contain slots that fit these components and to hold them in place. Once the class of students makes their own solar lanterns, they would organize a sale where MakeGlows will be sold to people in the rural communities at a nominal price of $6. The proceeds will be used in purchasing components needed for the next class of students. This ensures a sustainable economic model of production that empowers low-income schools in rural India. Also, the MakeGlow building classroom session can act as a great platform for groups like Barefoot Solar to collaborate with schools and conduct green job training/ repair workshops for students.

Makeglow kit for schools and students

MakeGlow consists of the following components: 1) A kit of solar and electronic LED parts 2) A template for the lantern geometry 3) A teaching guide 4) A student instruction manual 5) A user guide.

The teaching guide:

A guide for teachers in the form of a series of training videos/ a booklet will be designed based on a MakeGlow solar curriculum. The solar curriculum will contain an overall introduction to the importance of why MakeGlow is an empowering product-process for addressing sustainability, green energy adoption and using recycled materials. It will contain conceptual information explaining the working of solar circuits and basic functioning of individual components, fun classroom activities and teaching methods that could supplement the MakeGlow building activity. With lesson plans from the solar curriculum, the teachers could structure their class period to weave in a short lecture on renewable technologies (particularly solar), explain the working, benefits of solar and potential green job opportunities to inspire young minds and then, lead the class into a hands-on session where they build MakeGlows. The teaching guide will also contain different deployment plan options indicating various channels of introducing the solar lanterns to the rural communities through the students after they build MakeGlows.

The MakeGlow student instruction manual: The MakeGlow instruction manual for students is an easy to follow graphic pamphlet with folding diagrams that would guide students in the lantern making process. The manual will also contain illustrations about the placement of solar and LED electronic components in the cardboard structure.

The MakeGlow user guide: The user guide provides information on the effective and safe handling of the solar lantern, directions on placement of lantern for charging, tutorial and tips for maintenance/ repair and information on recycling electronic components after use.

Potential local partner

Organisations like Teach For India (TFI) can be potential local partners for this project. Teach For India is a non-profit organisation that is a part of the Teach For All network. The Teach For India fellowship recruits college graduates and working professionals to serve as full-time teachers in low-income schools. The MakeGlow program i.e.,the learn and build activity can be integrated in the curriculum of schools that are partnered with TFI.

Mapping the system

Challenges and Management models

One of the major challenges in the MakeGlow concept is finding an efficient method to manage the entire process. This involves ordering the solar and electronic LED parts from a wholesale supplier, procuring components, organising them in kits before handing them over to students, getting the template, teaching guide, student manual, user manual, training the teacher to conduct the building activity in class and managing lantern deployment plans. With respect to this, two potential models could work well with MakeGlow concept.

Model 1: Direct collaboration with a schoolteacher: In this model, the MakeGlow team will work directly with a schoolteacher. With initial external funding, the team would source the kit of parts from wholesale suppliers and organise them into kits for students. The MakeGlow team will train teachers on conducting the MakeGlow fabrication activity based on preliminary insights from testing at UC Davis, provide them with the template and the manuals. The team will also work with the school and the teacher to organise events related to selling MakeGlows in the community.

Model 2: Collaboration with a non-profit: In this model, the MakeGlow team will identify potential non-profit organisations like TFI to work with. The team will help source components for the non-profit and provide them with necessary intellectual/ educational resources like the template, instruction manual and teaching guide to fabricate MakeGlow. For the initial round, the team will work with the non-profit to identify one or two schools and train teachers in the schools for the MakeGlow fabrication as a classroom activity. In the subsequent years, the non-profit will continue managing, integrating and overseeing the MakeGlow activity across a larger network of schools.

User Testing

User testing at Studio H, Berkeley

In order to test if students are actually able to trace, cut, fold cardboard into solar lanterns and insert solar LED components in the structure, I conducted an hour long workshop session at the Girls Garage for a group of 15 girls between 9-13 years. I demonstrated the step-by-step lantern building process and the girls followed my lead. All of them were able to make their lanterns successfully without major failures that helped validate my concept.

Comments from the girls:

"...slot sizes for the solar panel and the LED are too small.."

"...was fun and awesome.."

"...i can make a summer beach chair out of this template.."

"...i am going to give it a makeover with colour pencils.."

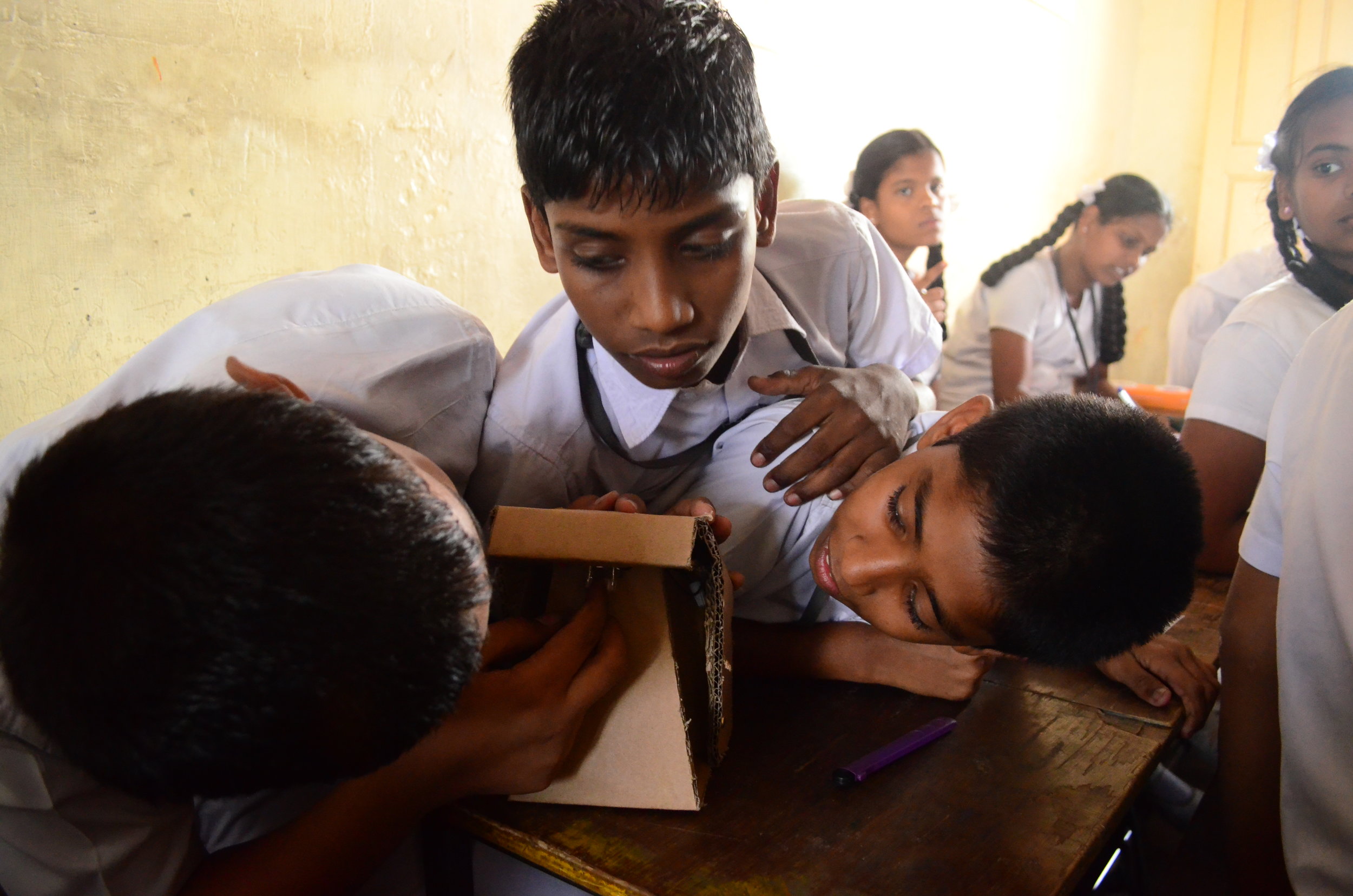

User testing at HCI matriculation school, Chennai, India

This classroom in Chennai consisting of 36 students (7th graders) was divided into 8 groups for the MakeGlow fabrication activity. All groups were successfully able to build fully functional MakeGlow lanterns. Students expressed their interest in learning the technical concepts behind the working of solar technology.

Comments from the students:

"...the cardboard is too difficult to cut..."

"...how does solar work?..."

"...can we cut this with scissors..?"

"...this is so much fun..."

"...wish there were more makeglow stickers..."

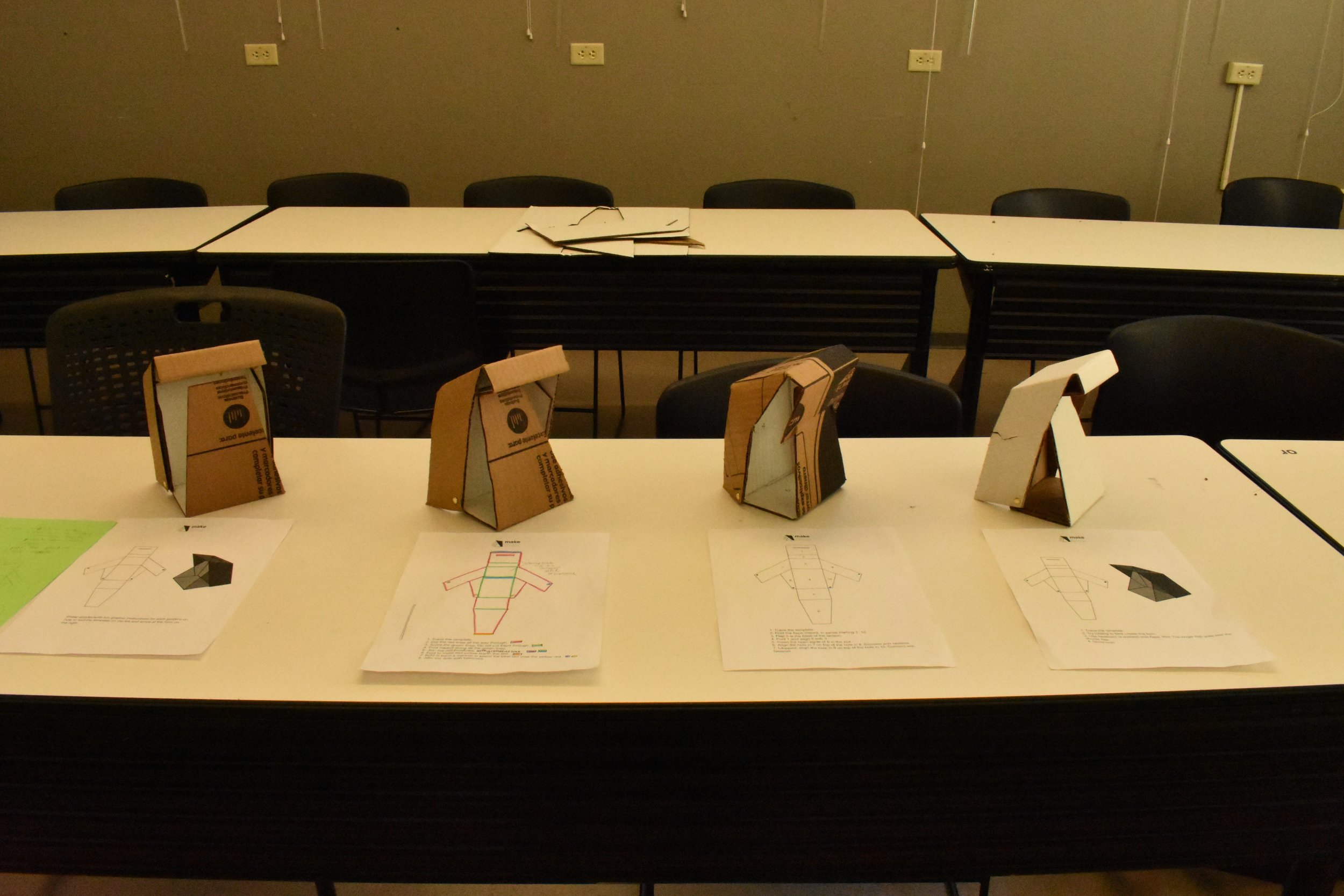

Iinstruction manual testing at UC Davis

In order to evaluate the utility of the student instruction manual, I conducted a series of tests in an undergraduate class of 17 design major students at UCDavis. I chose this test group because design students have high empathy for end-users and are capable of providing creative solutions to ambiguities while redesigning instruction manuals. I developed four different prototypes of instruction manuals – a) color coded, b) numbered, c) no-text version and d) a blank version. Four student teams were each given one instruction manual.

The team with the color-coded manual was the most successful and completed the activity in ~23 minutes. The team with the numbered manual arrived at a deformed structure of MakeGlow and attributed it to ambiguity in the instruction. The team with the no-text version was able to fold the template into the final lantern form but took around ~32 minutes to finish the activity – this however demonstrated that the template and folds are fairly intuitive to follow. Finally, the team with the blank manual was given a finished lantern piece and had to come up with easy to follow instructions for sixth graders. The color-coded instruction manual template being the most successful will be adopted and field-tested in further rounds of classroom tests in Indian schools.

Branding and Outreach

Collaborations

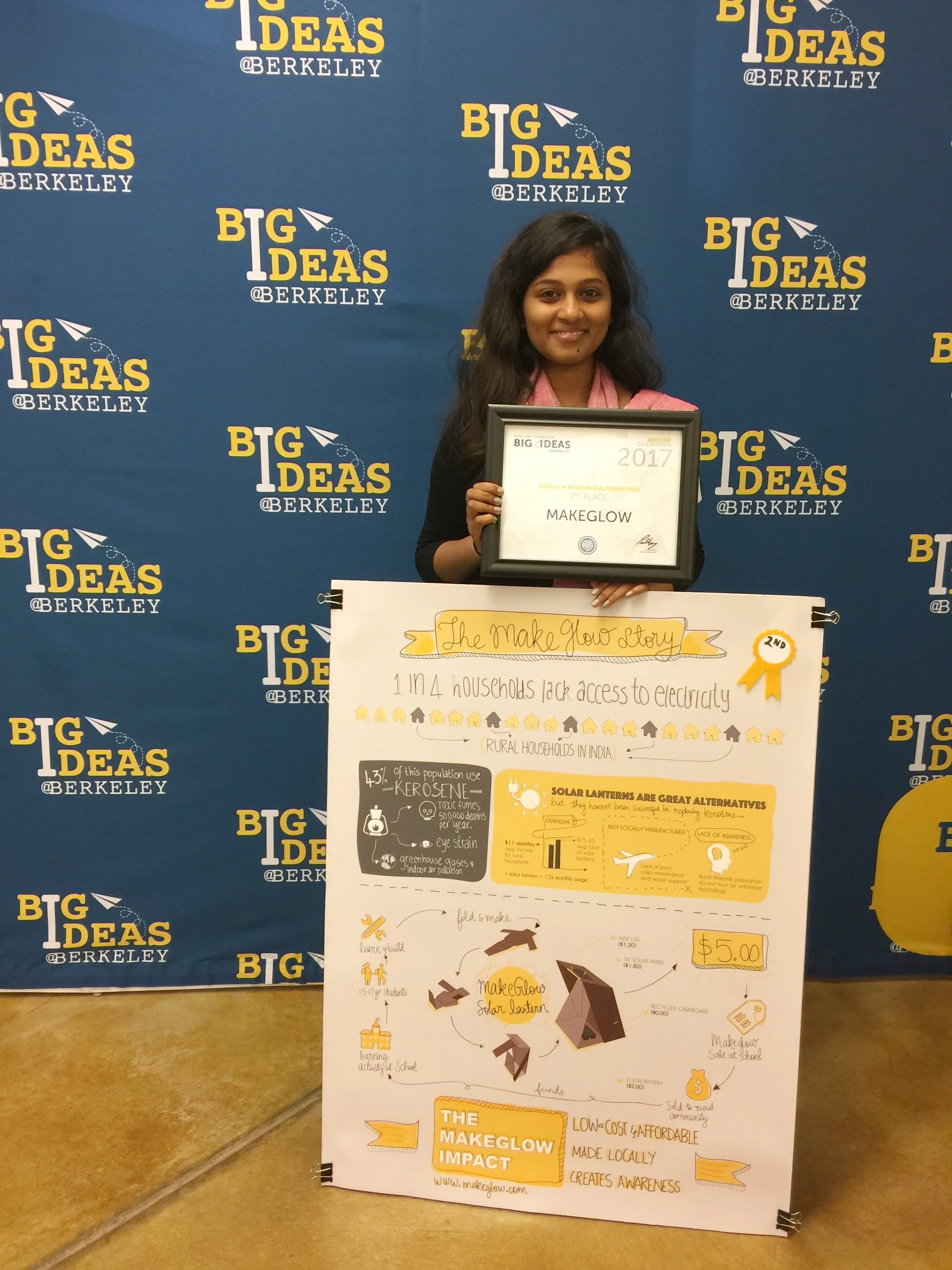

MakeGlow has been awarded the Second place (from a pool of over 300 ideas) under the Energy and Resource Alternatives category in the Big Ideas 2016-2017 competition at UC Berkeley.

MakeGlow has also been awarded Honorable Mention at The Grand Prize pitch day event, Big Ideas, UC Berkeley.

MakeGlow is the recipient of the Poverty Alleviation through Sustainable Solutions (PASS) Grant by the Blum Center for Developing Economies, UC Davis.

MakeGlow was exhibited at The Jan Shrem and Maria Manetti Museum of Art, UC Davis as part of the graduate student exhibition "This point forward" from May 31 - June 31, 2017.

Following this, I worked with SELCO Foundation, Bangalore as an Innovator in Residence from jan-oct 2018, to further develop MakeGlow and manufacture it in India.

Click here to read more about MakeGlow’s development from a paper dream into a manufacturable reality with support from the SELCO Foundation, Bangalore.